|

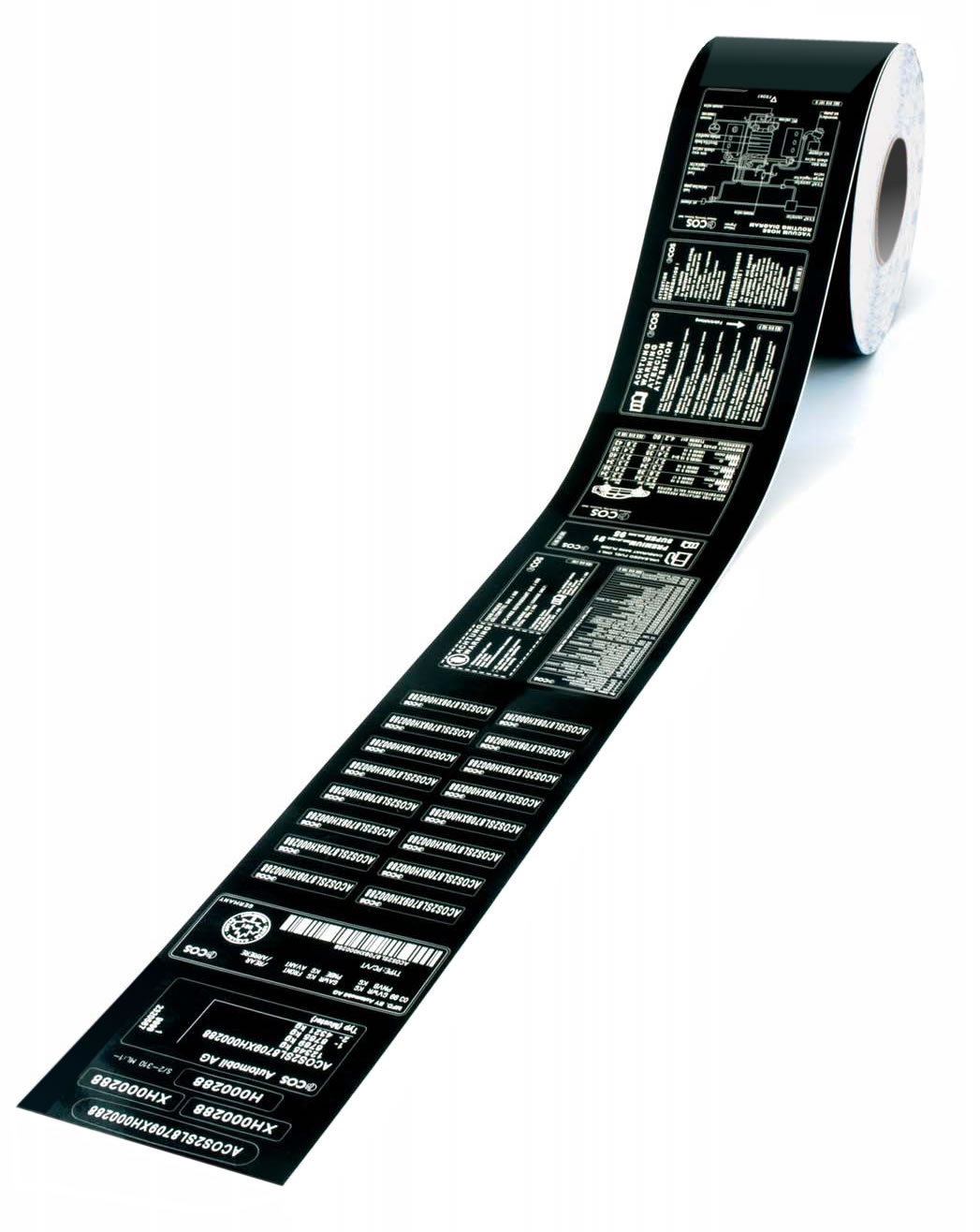

BLACK |

WHITE |

SILVER |

COLOURED |

| LAYERS |

Black

/ White Acrylic |

White

/ Black Acrylic |

Silver

/ Black Acrylic |

Clear

Polyester / pigmented acrylic (colour) |

| TOTAL

THICKNESS |

215

microns |

235

microns |

235

microns |

295

microns |

| ADHESIVE |

Acrylic

30 microns |

Acrylic

30 microns |

Acrylic

30 microns |

Acrylic

30 microns |

| TENSILE

STRENGTH |

2 N/10

mm |

2 N/10

mm |

2 N/10

mm |

100

N/10 mm |

| ELONGATION

AT BREAK |

20

% |

15

% |

16

% |

130

% |

| ADHESIVE

STRENGTH ON PAINTED PANEL (N/10 mm), PANEL SPEED : 20 mm/min,

300 mm / min |

2,

Broken |

2,

Broken |

2,

Broken |

No

data, 9 |

| HOT

TEMPERATURE RESISTANCE |

80

Degrees C x 168 Hrs, 150 Degrees C x 1,000 Hrs, 260? x 1O min |

80

Degrees C x 168 Hrs, 150 Degrees C x 1,000 Hrs, 260? x 1O min |

80

Degrees C x 168 Hrs, 150 Degrees C x 1,000 Hrs, 260? x 1O min |

- |

| COLD

TEMPERATURE RESISTANCE |

-30

Degrees C x 6 Hrs, -55 Degrees C x 100 Hrs |

-30

Degrees C x 6 Hrs, -55 Degrees C x 100 Hrs |

-30

Degrees C x 6 Hrs, -55 Degrees C x 100 Hrs |

- |

| THERMAL

CYCLE TEST |

1,000

cycles (-40 Degrees C x 0.5 Hrs / 85 Degrees C x 0.5 Hrs |

1,000

cycles (-40 Degrees C x 0.5 Hrs / 85 Degrees C x 0.5 Hrs |

1,000

cycles (-40 Degrees C x 0.5 Hrs / 85 Degrees C x 0.5 Hrs |

- |

| HOT

WATER IMMERSION TEST |

90

Degrees C x 15 min |

90

Degrees C x 15 min |

90

Degrees C x 15 min |

- |

| WATER

IMMERSION TEST |

40

Degrees C x 1,000 min |

40

Degrees C x 1,000 min |

40

Degrees C x 1,000 min |

- |

| SALT

WATER RESISTANCE |

5%

NaCl aq spray x 240 Hrs |

5%

NaCl aq spray x 240 Hrs |

5%

NaCl aq spray x 240 Hrs |

- |

| OIL

RESISTANCE |

Gasoline

immersion x 30 min at room temperature, Diesel oil dripping 24

Hrs, Engine oil immersion 30 min at room temperature |

Gasoline

immersion x 30 min at room temperature, Diesel oil dripping 24

Hrs, Engine oil immersion 30 min at room temperature |

Gasoline

immersion x 30 min at room temperature, Diesel oil dripping 24

Hrs, Engine oil immersion 30 min at room temperature |

- |

| CHEMICAL

RESISTANCE |

Surface

application of 0.1 N H2 SO4 for 24 Hrs, Surface application of

0.1 NaOH for 24 Hrs |

Surface

application of 0.1 N H2 SO4 for 24 Hrs, Surface application of

0.1 NaOH for 24 Hrs |

Surface

application of 0.1 N H2 SO4 for 24 Hrs, Surface application of

0.1 NaOH for 24 Hrs |

- |

| WEATHERABILITY

/ UV TEST |

S-WOM

3,000 Hrs Florida exposure 24 months |

S-WOM

3,000 Hrs Florida exposure 24 months |

S-WOM

3,000 Hrs Florida exposure 24 months |

- |